Warehouse Risk Assessments, Inspections and Audits

Keeping track of how well your warehouse processes and machinery are running is so important to ensure health and safety. A warehouse and equipment inspection check is a good way to document how your warehouse handles equipment and situations safely. Employers have a legal obligation to protect their Health and Safety and that of their workforce.

Warehousing and storage can cover a wide range of activities that can result in various hazards and risks. Effective health and safety management involves you, the employer, looking at the risks that arise in the workplace and then putting sensible health and safety measures in place to control them. By doing this you can protect your most valuable asset, your employees, as well as members of the public from harm.

With all accidents, injuries and ill-health being reported to the health and safety enforcing authorities under the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 1995 (RIDDOR).

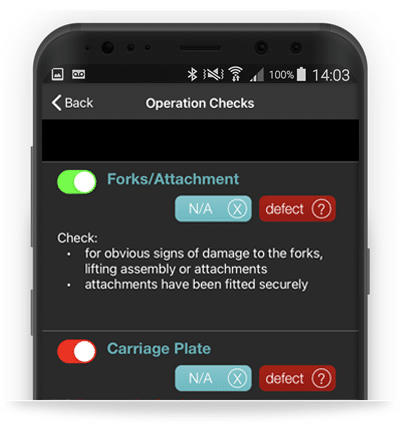

Vehocheck risk assessments audits and checks not only enable you to perform multiple checks on warehouse equipment, processes and facilities with ease, but reporting is in real-time which eliminates unwieldy and time-consuming paper-based check systems.

Using Vehocheck helps warehousing companies with compliance and reporting against safety regulations, including HSE, PUWER (Provision and Use of Work Equipment Regulations 1998) and LOLER (Lifting Operations and Lifting Equipment Regulations).

Similar to our DVSA daily walkaround checks for commercial and plant vehicles, Health and Safety Executive (HSE) (PUWER) and LOLER inspections checks are a set of checks that can be carried out on a daily, weekly, monthly or quarterly basis.

Warehousing is a complex industry that can expose workers to a multitude of risks so health and safety should be proactively managed, manage better with Vehocheck.

Designed to not only fully streamline the assessment, inspection and check process and remove the need for manual paper trails, Vehocheck also gives operators the facility to submit and view machinery, equipment and staff documentation, certifications and much more.

All reports submitted instantly alert the warehouse manager and or SHE manager in real-time and can be audited and managed from within the Vehocheck dashboard giving you complete control and visibility of all your warehousing machinery and assets.

With Vehocheck, you can be confident that your risk assessments, inspections and audit process is robust and complies with the HSE, PUWER and LOLER safety and maintenance guides.

Ensure DVSA Compliance and Manage your Fleet with Vehocheck

Vehocheck is ideal for

- Forklift pre-use inspections

- Material Handling

- Warehousing Racking

- Milling Machinery

- Processing Machinery

- Facility Maintenance

Risk Assessments, checks, Inspections and Audits.

- Digital Risk Assessments

- Safe Systems of Work

- Unexpected Risk Event

- Close Call/Near Miss

- PPE Checks

- PUWER checks

- LOLER checks

- Custom Health and Safety

- Bespoke and tailored checklists available.

Warehouse Management

- Real-time defect notification

- Improve the speed of response to assist staff.

- Reports available if required for health & safety purposes.

- Manage key inspections, checks and maintenance

- Job card creation and management

- Store and view all PUWER and LOLER examinations

- Repair cost analysis

- Calendar view (calendared) scheduling

- Full document storage and data integration