Understanding the correlation between tyre tread depth and vehicular control is crucial, particularly when navigating wet road conditions. It’s essential to maintain optimal tyre health, as they serve as the singular point of contact between your vehicle and the tarmac.

In the United Kingdom, regulations stipulate a minimum legal tread depth of 1.6mm across the central three-quarters of the tyre and around the complete circumference for the majority of vehicles. For heavier vehicles, those exceeding 3.5 tonnes, the requirement is set slightly lower at 1mm.

While meeting this threshold might be sufficient for passing the annual MOT test, it is by no means a benchmark for assured safety during inclement weather.

Incorrect Tyres, Thread and Condition

For Transport Managers and Fleet Operators managing multiple vehicles, keeping above the bare minimum legal requirements is a sound practice.

A more conservative approach would be to proactively monitor tread depth regularly and replace tyres well before they approach the legal limit

Image Credits: DVSA Moving On Blog

Flat Spot

Less that 1mm tread across three-quarters of the tyre tread, and exposed cords in the tread area.

Tyre Bulge

A bulge in the tyre sidewall will appear spongy and is easily depressed.

Tyre bulging, if not addressed, will cause the tyre to separate and fail. If discovered at a roadside inspection this would lead to an immediate prohibition.

Image Credits: DVSA Moving On Blog

By using the Vehocheck you will always be confident in knowing your tyres are safe

Maximise fleet safety and optimise your tyre management with Vehocheck.

Delve into a comprehensive history of your tyres’ lifespan, ensuring full traceability and mitigating the risk of premature wear. Moreover, gain unparalleled insight into your cost metrics, empowering you to make informed budgetary decisions.

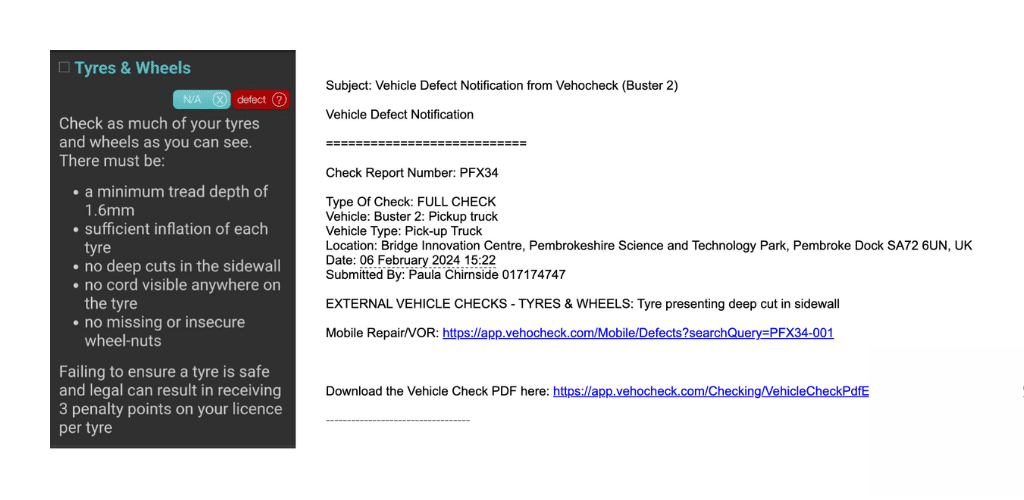

Defect Reporting

When a driver identifies a defect during their daily walk-around check, designated email recipients will receive an automated notification detailing the specific issue.

This seamless communication ensures transport managers and fleet operators can promptly address any concerns.

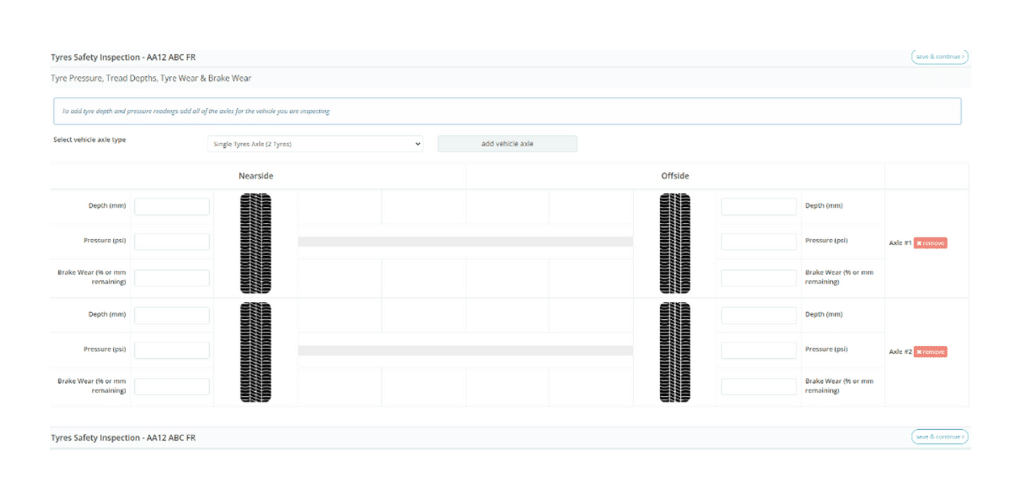

Tyre Depth Reporting

Tyre psi, tread depths and brake wear can be recorded during a PMI inspection. This can be graded as items to monitor or a job card can be created to action the tyre replacement. Tyre types, DOT codes, serial numbers, replacement reason, supplier etc. can all be recorded.

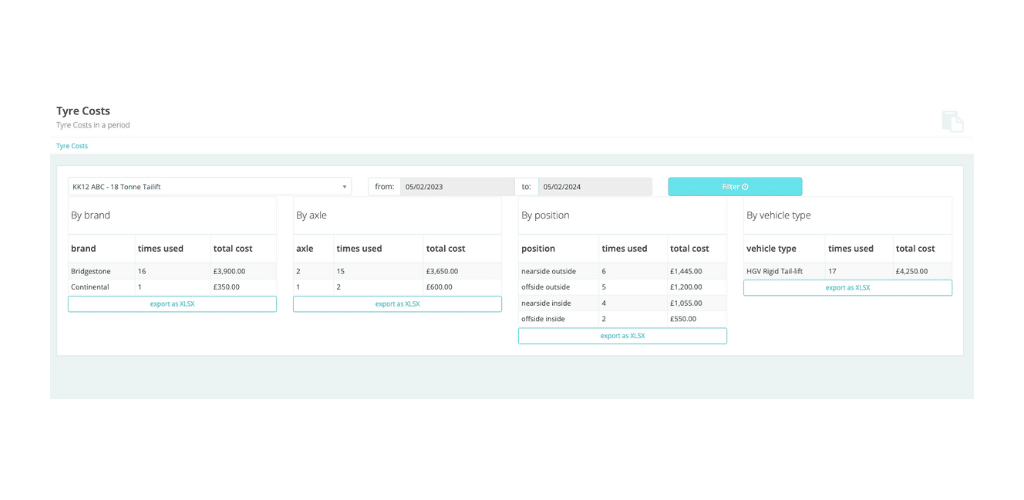

Tyre Costing Analysis

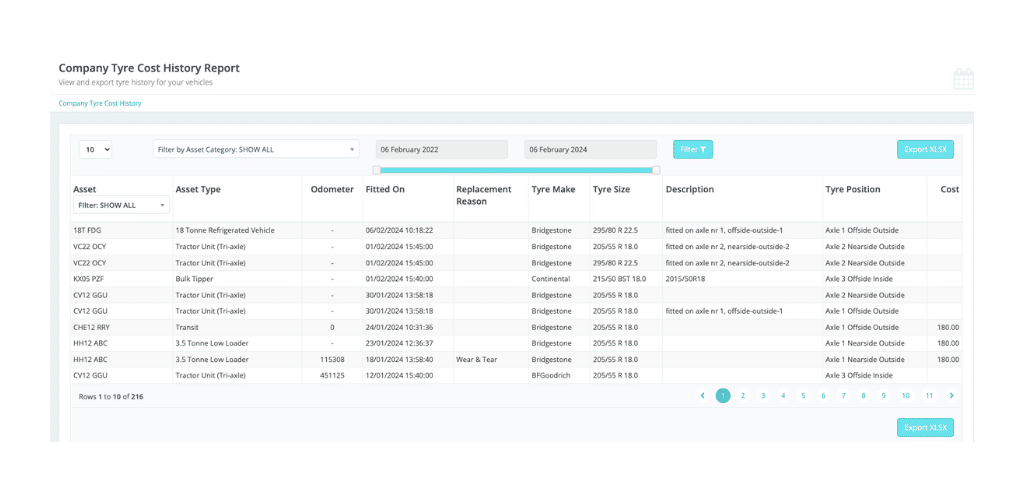

In the Tyre Cost History Report, you have the option to filter by a specific asset or view all vehicles. This report enables you to view key information such as the date the tyre was fitted, the reason for its replacement, the make and size of the tyre, its position, and most crucially, the associated cost.

Conclusion

Leveraging Vehocheck for your tyre management needs not only amplifies fleet safety but also optimises your operational efficiency.

By providing a detailed history of your tyres’ lifespan, it reduces the risk of premature wear and enhances traceability. Simultaneously, its ability to provide in-depth cost metrics empowers you to make informed budgetary decisions.

Ultimately, Vehocheck is an invaluable tool that combines safety, efficiency, and financial insight into one comprehensive platform, transforming the way you manage your fleet’s tyres.

About Vehocheck

Vehocheck is a fleet management and compliance software solution for operators, drivers and workshops, which provides a fully traceable vehicle maintenance, compliance and repair audit for all your assets or vehicles.

The process from vehicle defect identification and managing the repair is enhanced through our workshop job card system, customised reporting to highlight driver behaviour and vehicle issues, with additional in-depth repair cost analysis.

By instantly delivering crucial asset or vehicle defect information, the procedures for correcting these issues can be expedited; enabling companies to maintain a productive, safe and compliant fleet.